We provide:

- Detailed arrangement and structure drawings.

- Tooling design for CNC milled composite part molds.

- Lofted flat-panel structure for CNC cutting.

- Laminate kitting.

- Lofting for metal boat construction using ShipConstructor software.

Paul and I share the same philosophy regarding design for efficient and high quality production: The designer should be intimately involved in the construction process, and any time spent in design that can make the builder’s job easier adds value. We both spent a part of our careers computer lofting metal structures for the commercial ship building industry in the Northwestern United States. In this environment you learn how efficiently a ship can be built if the structure is designed and lofted for production and the lofting is accurate.

It seemed natural to us to carry the standard practices of commercial shipbuilding into the world of yacht construction:

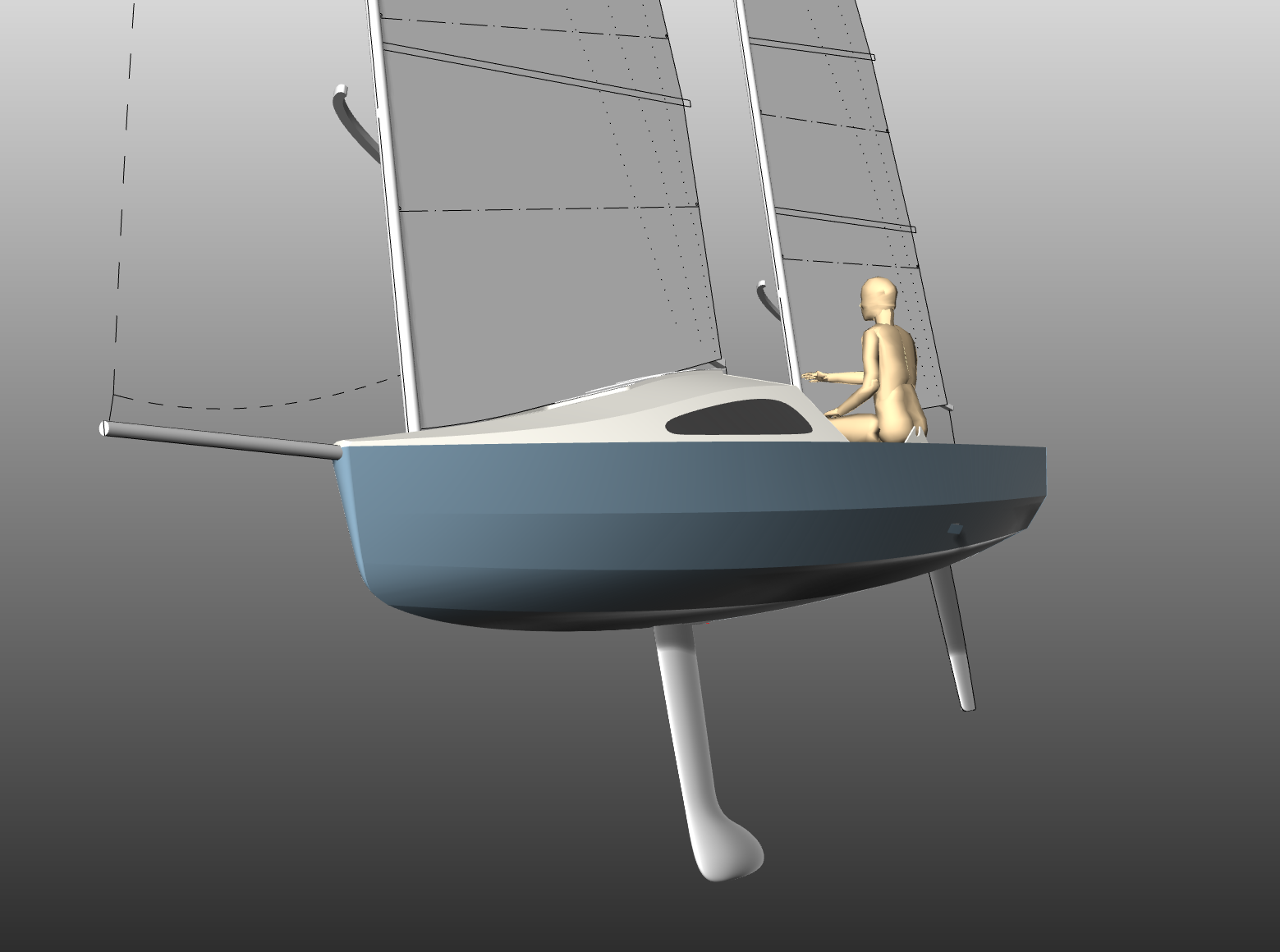

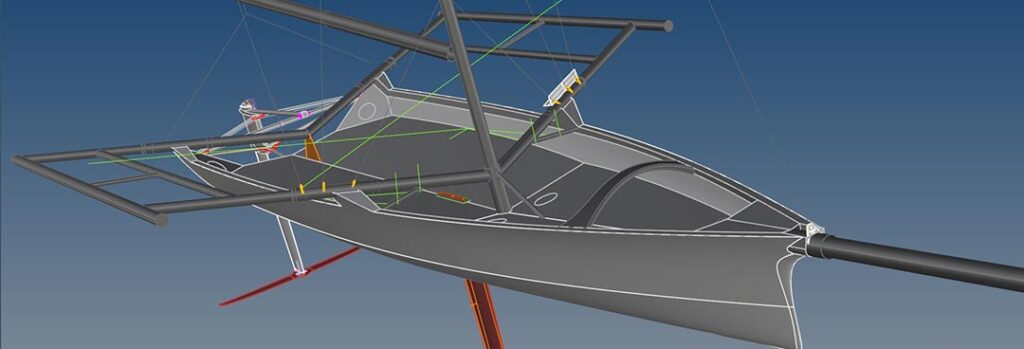

- Create a complete and accurate 3D computer model of the boat.

- Think through the building process and produce drawings that clearly illustrate the details of the design and the production steps necessary to build it.

- Use the 3D geometry of the yacht to efficiently produce nicely detailed computer cut tooling.

- Provide the yard with patterns and kits of pre-cut parts.

We believe a boat design is much more than a set of pretty drawings that the builder is left to interpret on his own.

-Eric